Man has always been curious to bend metals to different shapes and sizes. From time primitive, the advancements in the field of metal molding have been tremendous. The industrial revolution paved the way for radical changes in the production industry. The major change was the inception of lathes in the machining sector.

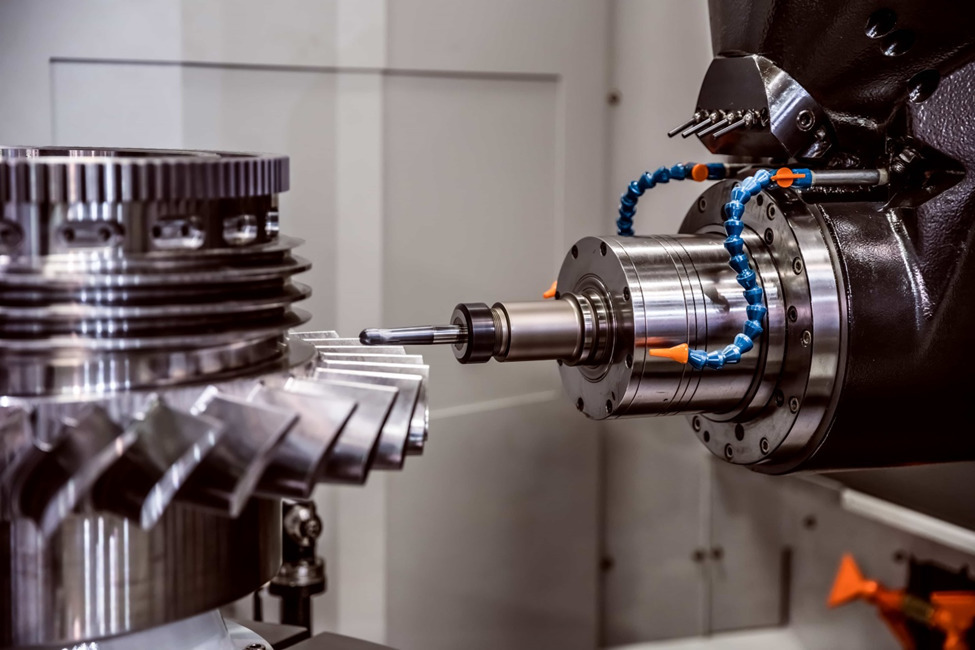

Decades later, the industry was stunned by the precision in the job the CNC machines could impart. This was the turning point in the metal machining sector. The machining industries in Montreal had their own share of bigwigs, like the LOCUS Precision milling company, that still maintains the same level of quality since the 1970s.

The quality, cost-effectiveness, and production time for goods have improved exponentially after the introduction of CNC machining. CNC stands for computer numerical control. Fundamentally, CNC is a branch of computer science. The result of machines and codes coming together was, however, bliss for the machining world since the cost of mass production came down to unbelievable amounts.

CNC machines had many advantages over their predecessor, the manual lathes. The most important ones are:

- Improved accuracy in machining.

- Enhanced finishing for the final product.

- Reduced machining time.

- Precision in doing intricate works.

- Ease of documentation and job tracking.

- Cost-effectiveness

- Reduced human interference while machining.

- Reduced workshop mishaps.

- Faster job transition time.

- Reduced human errors (nearly zero).

- Ease of operation.

Apart from the above-listed merits, CNC machines are the biggest advantage of being the cheapest alternative to 3D printing. The cost of 3D printing is not yet viable for industrial-scale production of domestic goods. Here, CNC machines are still ruling the industry despite being much more time-consuming.

CNC machining has some disadvantages as well. The material wastage in CNC machining is comparably high. The initial investment required for CNC machining is also high when compared to unconventional lathes.

The labor dependence gets lower, leading to employment issues. This point is positive in one aspect but unfavorable from another point of view. CNC machines also require a lot of electricity to operate. This can pose a problem for small-scale industries.

Despite the hiccups, CNC machines are the modern solution to machining needs in Montreal. The quality of jobs the companies here showcase is exceptionally good. CNC machining can help you to bring the designs in your mind to reality with utmost precision. Choose the right person for the job and the machine will do the rest for you.