In industrial settings, belt-driven systems are widely used to transmit power between rotating machinery. Proper belt alignment is crucial for the smooth and efficient operation of these systems. Misalignment can lead to increased wear and tear, energy inefficiencies, and costly downtime. Belt alignment tools are designed to address these issues and optimize the performance of belt-driven systems. In this blog, we will explore the impact of alignment tools on your bottom line, focusing on the benefits they bring to your business.

Understanding Belt Misalignment

Before we explore the benefits of alignment tools, it’s crucial to understand what belt misalignment is and why it’s problematic. Misalignment occurs when the driver and driven pulleys in a belt-driven system are not accurately aligned. This can cause the belt to wear unevenly, reduce its lifespan, and decrease system efficiency – all factors that can increase operational costs and negatively impact your bottom line.

How Alignment Tools Can Improve Your Bottom Line

Increased Equipment Lifespan

One of the most significant ways alignment tools can positively impact your bottom line is by extending the lifespan of your equipment. Misalignment can cause premature wear and tear on both the belts and the pulleys. By ensuring proper alignment, these tools can help reduce wear, thereby extending the life of your belts and pulleys and reducing the need for frequent replacements.

Improved Efficiency

Misaligned belts can significantly reduce the efficiency of your machinery. They can cause the belts to slip or the equipment to work harder than necessary, leading to increased energy consumption. Alignment tools can help ensure optimal alignment, leading to improved efficiency and reduced energy costs.

Reduced Downtime

When belts fail due to misalignment, it can result in unplanned downtime as you wait for replacements or repairs. This can cause significant disruption to your operations and lead to substantial financial losses. Regular use of belt alignment tools can help prevent such failures, minimizing downtime and keeping your operations running smoothly.

Lower Maintenance Costs

Regular maintenance is a part of any industrial operation. However, the costs can quickly add up, particularly when dealing with frequent belt failures due to misalignment. By using alignment tools to maintain proper alignment, you can reduce the frequency of such failures, leading to lower maintenance costs.

Reducing Energy Consumption

Energy efficiency is a key concern for businesses seeking to reduce operating costs and environmental impact. Misaligned belts lead to energy wastage due to increased friction and slippage. Alignment tools enable technicians to align belts accurately, reducing energy consumption and contributing to cost savings. With energy costs forming a significant portion of operating expenses, improved energy efficiency directly impacts your bottom line.

Enhancing Safety and Reliability

Belt-driven systems that are not properly aligned can pose safety risks to workers. Misaligned belts are more likely to slip or fail unexpectedly, potentially causing accidents and injuries. Alignment tools ensure that belts are appropriately tensioned and aligned, improving the safety and reliability of your equipment. A safer work environment leads to reduced absenteeism and workers’ compensation claims, further contributing to cost savings.

Choosing the Right Belt Alignment Tools

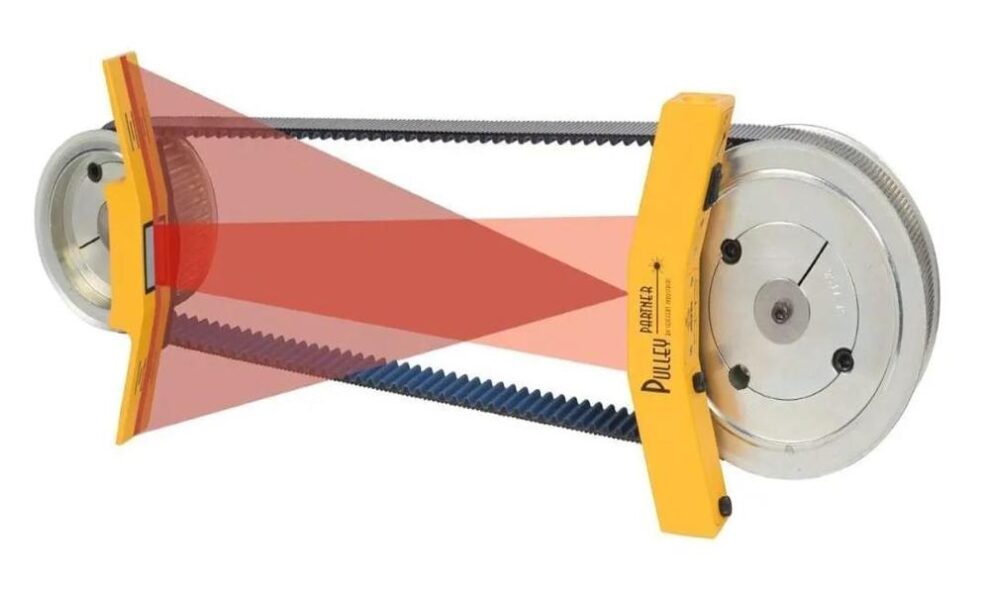

Various types of alignment tools are available, each with unique advantages. Some common types include straight-edge tools, laser alignment tools, and digital alignment tools. When choosing a tool, consider factors such as the complexity of your systems, the precision required, and your budget. Regardless of the tool you choose, the key is to make regular alignment checks a part of your maintenance routine.

Wrapping Up:

Belt alignment tools significantly impact your bottom line by improving equipment performance, reducing energy consumption, preventing premature wear and tear, and minimizing downtime. The efficiency and accuracy of these tools streamline maintenance processes and complement predictive maintenance strategies. Investing in alignment tools not only enhances your business’s cost-effectiveness but also contributes to a safer work environment and increased overall productivity. If your business relies on belt-driven systems, it’s time to consider the transformative impact of alignment tools on your bottom line and take proactive steps to optimize your equipment’s performance.